Chromatographic Column Packing

The performance of an hplc column depends largely on the nature and type of packing material. Common hplc column types are (packing material) C1, C3, c4 column hplc, C8, hplc c18 column, C30, amino, cyano, silica columns, etc. The size, shape, bonding phase, and carbon content of the packing can affect the performance of liquid chromatography.

Effect of packing particle size on the performance of HPLC columns:

The smaller the average particle size of the liquid chromatography column packing, the smaller the vortex diffusion, the better the mass transfer, and the higher the column efficiency. However, the smaller the packing particle size, the worse the permeation performance and the higher the column pressure. At the same time, the wider the packing size distribution, the poorer the permeation performance and the lower the column efficiency. The common packing particle sizes are 3μm, 5μm, 10μm, etc.

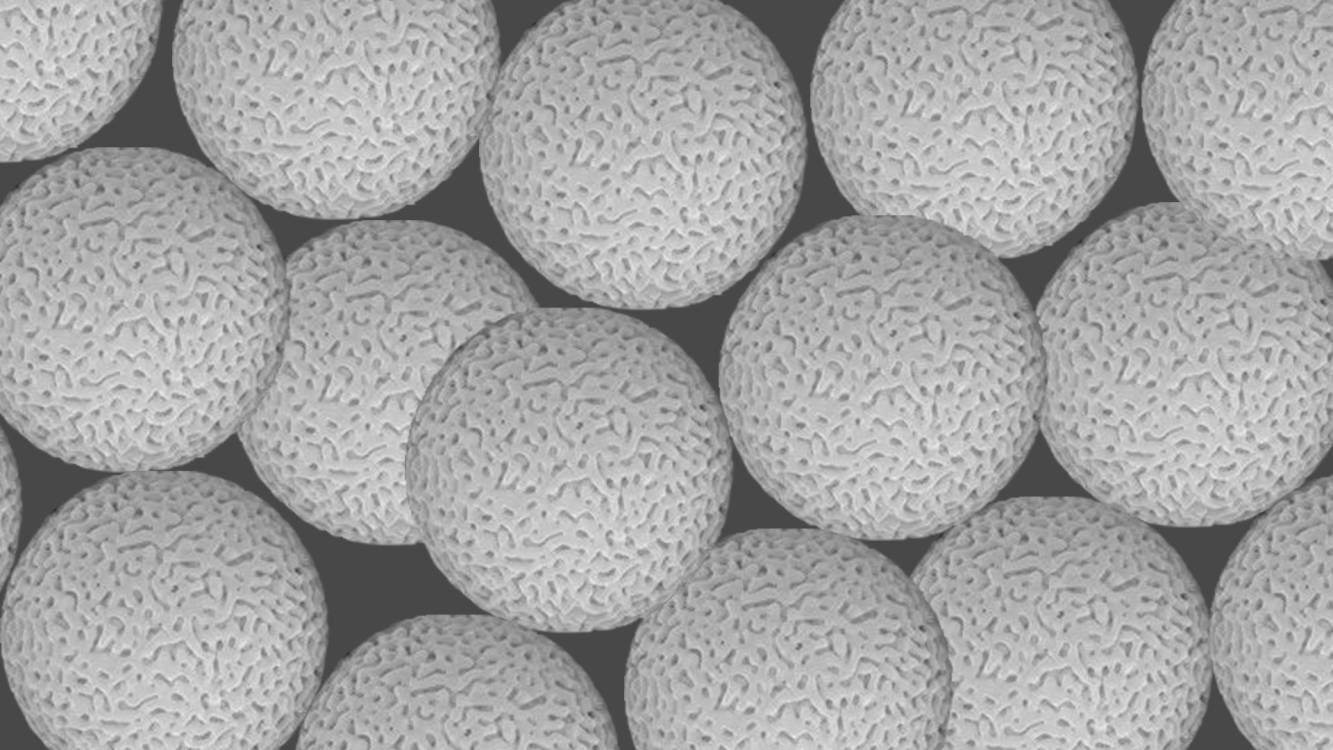

Influence of packing shape on the performance of hplc columns:

Packings for hplc columns are classified as amorphous or spherical. The structure of the hplc column bed prepared by amorphous packing is not uniform, the linear velocity of the mobile phase is not uniform, and the peak shape of the chromatogram is wider; the structure of the HPLC column bed prepared by spherical packing is uniform, so the column has high column efficiency and good reproducibility. Spherical packing is currently the most common liquid chromatography packing, and this packing has better performance and reproducibility.

Influence of the bonding phase of the packing material on the performance of the hplc column:

Silica gel is used as a matrix to which groups such as c18, c8, amino, and cyano are bonded by chemical bonding as fillers in hplc columns. HPLC columns with different properties are obtained by bonding different chemical groups. Due to the different separation mechanisms of the different bonding groups, the retention and separation of compounds are affected at once.

The filler bonding makes the stationary phase of the hplc column relatively more stable and less susceptible to lose while largely eliminating the adverse effects of silicone hydroxyl groups, which can be applied in a wide range of mobile phases and are widely used. However, the bonded packing is less acid resistant, with a pH of less than 2. When the pH of the mobile phase is outside the acidic range, the bonded phase is easily lost, and its durability and stabilit.

Effect of end group sealing of fillers on the performance of hplc columns:

Due to its special surface chemical properties, silica gel is widely used as a matrix material for hplc column packing. Silica gel has silicone hydroxyl groups on its surface. The density and distribution of silicone hydroxyl groups and their chemical properties affect the behavior of various types of chromatography to varying degrees.

When silica based HPLC columns, especially reversed-phase columns, non-specific adsorption is often encountered due to free silica hydroxyl groups (or silanol groups). For some more polar solutes, such as alkalis, the chromatographic summit is severely trailed and can even fail to elute due to strong adsorption. Tailoring (also known as capping) is often used to reduce the effect of silica hydroxyl groups by reacting the filler with a small silane (e.g., trimethylchlorosilane) in a subsequent reaction to react off some of the residual silica hydroxyl groups to increase surface coverage. Using this approach reduces irreversible adsorption or tailing and increases the carbon content. However, this method does not completely remove the residual silica hydroxyl groups. There is still 50% of the silica hydroxyl group left unreacted.

Influence of the carbon content of the filler on the performance of hplc columns:

The carbon content of hplc column packing, particularly reversed phase packing, is often used to characterize the degree of surface chemical modification. The higher the carbon content of the packing, the higher the density of the carbon chains, the longer the carbon chains, the higher the capacity factor, and the greater the hydrophobicity. In reversed phase conditions, filler growth means that the filler has a larger specific surface area, increased bonding, and increased retention of the target compound. Therefore, liquid chromatography with high carbon content packing is stable and reproducible, which facilitates the separation of poorly retained compounds and can improve the trailing of polar compounds; hplc columns with low carbon content packing are beneficial for the analysis of neutral and basic compounds and can reduce solvent losses.

Influence of other factors of packing on the performance of hplc columns:

In addition to the above, the activity, impurity content, pH stability, and thermal stability of the silica packing can also affect the performance of the liquid chromatography column...