China’s inspection and testing equipment market demand is vast, and the price growth rate drops.

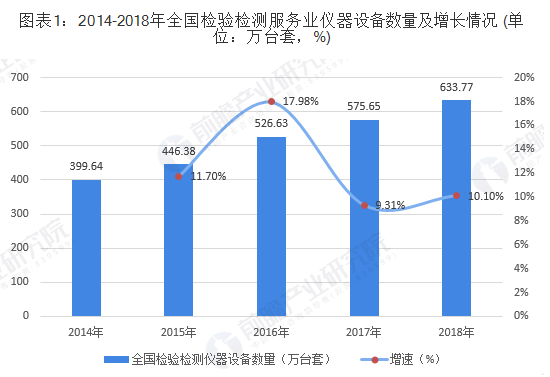

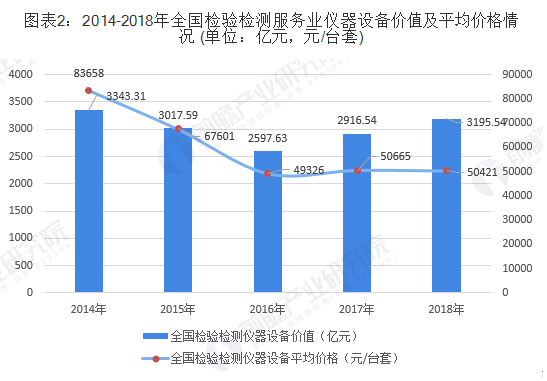

According to statistics from the State Administration of Market Supervision and Administration, from 2014 to 2018, the number of instruments and equipment in the inspection and testing service industry across the country is on an increasing trend. By the end of 2018, China had a total of 6.337,700 sets of inspection and testing equipment, up 10.10 percent year on year. The original value of all instruments and equipment assets was 319.554 billion yuan, up 9.57% year on year.

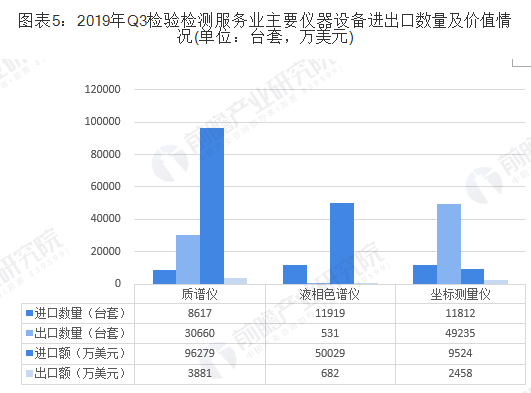

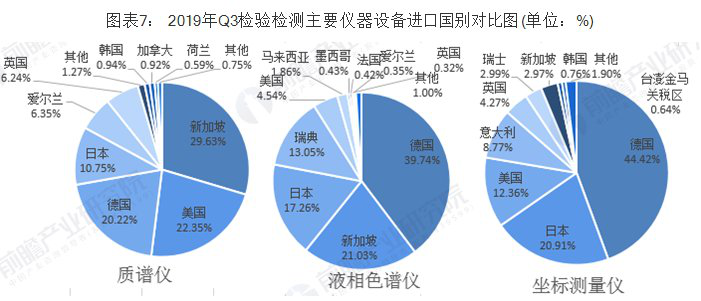

Among the inspection and testing equipment, mass spectrometers, liquid chromatographs, and coordinate measuring instruments are important measurement and analysis instruments, which are widely used in the fields of food, environment, clinical, chemical, energy, medicine, and materials science.

In the first three quarters of 2019, my country’s high-end inspection and testing equipment was mainly imported. The import value of mass spectrometer and liquid chromatograph reached 962.79 million U.S. dollars and 50.29 million U.S. dollars, which were 25 times and 73 times the export value, respectively.

There are a large number of CMM exports, with 49,235 sets exported, far exceeding the import of 11,812 sets. However, the export amount is only 24.58 million US dollars, far lower than the import amount of 95.24 million US dollars, indicating that China’s CMM exports mainly medium and low-end products.

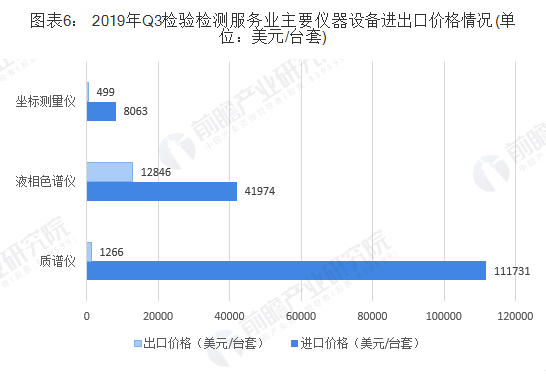

From the price point of view, the average price of imported mass spectrometers is about 111,731 US dollars per set, the average price of imported liquid chromatographs is about 41974 US dollars per set, and the average price of imported coordinate measuring instruments is about 8063 US dollars per set, far exceeding the average export price.

Overall, our inspection and testing equipment mainly import high-end equipment and exports low-end equipment. Compared with foreign countries, domestic inspection and testing equipment are still in the middle and low end, with relatively low prices and low profits. This restricts the rapid development of enterprises and the development of high-end products, mainly because the technological accumulation of domestic enterprises is relatively weak compared with foreign developed countries, which still requires domestic The enterprise’s efforts and national policy support have promoted the continuous accumulation of technology of my country’s inspection and testing equipment research and development enterprises to develop more internationally competitive products.

Not only are high-end equipment and equipment imported, but many high-end equipment accessories are also imported from abroad. For example, ultra-high liquid chromatography/liquid quality is used in food safety testing, but most food and drug inspections, disease control, immigration, and quality inspections It is to purchase imported brands. UPLCS is a Shenzhen high-tech manufacturer focused on R&D and manufacturing of high quantity chromatography consumables. We have rich production experience and strong manufacturing technology capabilities in long service life, guard column with less dead volume and low back pressure, UPLC in-line filter, non-bubble solvent filter with high purification capacity,0.1um inner surface roughness HPLC guard column tube, ghost peak removal column, tubing connector thread flitting, etc.

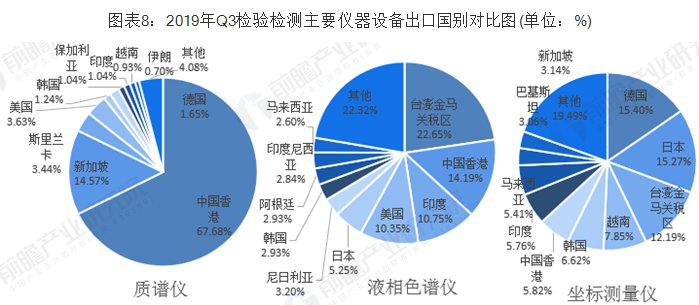

Equipment imports are mainly Germany, the United States, and Singapore,and equipment exports are mainly Hong Kong, Singapore,and Germany.

From the perspective of importing countries, in the first three quarters of 2019, my country mainly imported inspection and testing instruments such as mass spectrometers, liquid chromatographs and coordinate meters from Germany, the United States, Singapore, Japan and other countries.

In terms of exports, in the first three quarters of 2019, mass spectrometers were mainly exported to Hong Kong, China, accounting for 67.68%, more than half of the total. Liquid chromatographs are mainly exported to Taiwan, Penghu, Jinma, Hong Kong, and India, with exports accounting for 22.65%, 14.19% and 10.75% respectively. Coordinate instruments are mainly exported to Germany and Japan, with exports accounting for 15.4% and 15.27%.

Among them, it is worth noting that in 2018, the United States was my country’s largest overseas source of mass spectrometers. In the first three quarters of 2018, my country’s imports of U.S. mass spectrometers amounted to 329.32 million U.S. dollars, and this year was affected by the Sino-US trade war. The US imported mass spectrometers were only 21.18 million U.S. dollars, a decrease of about 35%. In 2019, mass spectrometers imported from Germany and Singapore increased relatively.

The development of scientific research projects is closely related to the development of inspection and testing equipment, and domestic needs to strengthen its own equipment R&D and manufacturing.

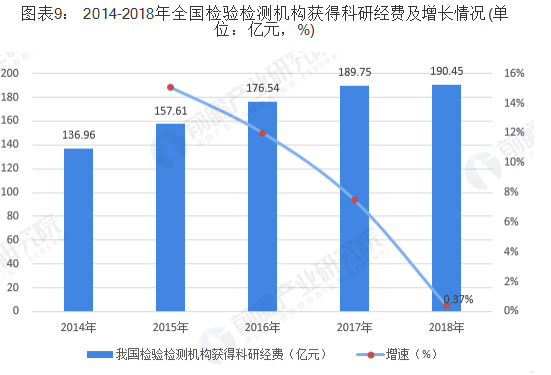

From 2014 to 2018, my country’s inspection and testing institutions received a continuous upward trend in scientific research funding, but the growth rate continued to decline, and the rate of decline was relatively rapid. In 2018, national inspection and testing institutions received research funding of 19.045 billion yuan, a year-on-year increase of only 0.37%.

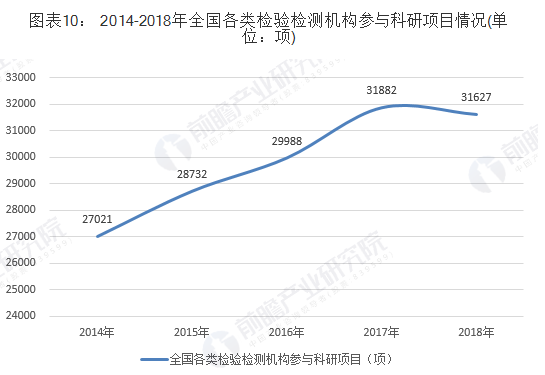

In 2018, various inspection and testing institutions across the country participated in a total of 31,627 scientific research projects, a decrease of 255 from the previous year, which was affected by equipment to a certain extent. The development of scientific research projects is closely related to the development of my country’s inspection and testing equipment. In the future, my country should further strengthen the R&D and manufacturing of its equipment, increase scientific research efforts, and promote the development of scientific research projects.

In general, my country needs to increase its own R&D and manufacturing capabilities, transforming from a large importing country to a large exporting country, and from low-end exports to high-end exports. This is a process that requires long-term efforts.Since “Made in China 2025″ was first proposed in 15 years, the “five major projects” such as the construction of the national manufacturing innovation center, intelligent manufacturing, industrial strong foundation, green manufacturing, and high-end equipment innovation have been steadily advanced, and the initial results have appeared. I believe that in the future With the continuous and in-depth development of “Made in China 2025″, my country will transform from a large manufacturing country to a strong manufacturing country, and ultimately achieve the goal of a strong manufacturing country.

Post time: Dec-26-2020