One of the important roles of chromatography is to quantify the sample, and chromatography quantification is based on the weight of the component or its concentration in the carrier gas being proportional to the response signal of the detector. Common quantitative methods include area normalization, internal standard, external standard, and standard curve methods. It is easy to be confused between internal and external standard methods. Here we analyze their similarities, differences, and advantages in terms of definition and characteristics.

Internal marking method

1, Definition

The standard internal method is an indirect or relative calibration method. In the analysis and determination of the content of a component in a sample, a component similar to the component to be measured but completely separated is selected as an internal standard (the internal standard is a component that is not present in the sample). Then a mixed standard solution of the component will be measured, and the internal standard is prepared and fed into the sample to obtain the relative calibration factor. The internal standard is then added to the component’s sample to be measured, and the quantitative parameters of the component to be measured and the internal standard are measured after sampling.

2, Internal standard

The standard internal method is an important technique in the quantitative analysis of gas chromatography. When using the standard internal method, a certain amount of standard material is added to the sample, which the chromatographic column can separate. It is not interfered with by the peaks of other components in the sample, as long as the peak area and relative response value of the internal standard and the component to be measured can be found out the percentage content of the component to be measured in the sample. The internal standard selection is very important when using a standard internal method for quantification.

Ideally, the internal standard should be a known compound that can be obtained pure so that it can be added to the sample in an accurate, known amount. It should have essentially the same or, if possible, the same physicochemical properties (e.g., chemical structure, polarity, volatility, and solubility in solvent), chromatographic behavior, and response characteristics as the sample component being analyzed, and preferably be a congener of the substance being analyzed. Of course, under chromatographic analysis, the internal standard must be fully separated from the components of the sample.

3, the choice of internal standards of the four requirements

(1) The internal standard should be a pure substance that does not exist in the sample.

(2) It must be completely soluble in the sample and completely separated from the chromatographic peaks of the components in the sample.

(3) The amount of internal standard added should be close to the measured component.

(4) The position of the chromatographic peak should be close to the chromatographic peak of the component being measured or in the middle of several chromatographic peaks of the component being measured.

4, Influencing factors

In the use of standard internal quantification, affect the internal standard and the measured component peak height or peak area ratio of the factors are mainly chemical, chromatographic, and instrumentation of the three categories. Changes in the area ratio due to chemical factors often occur when analyzing duplicate samples.

Chemical factors.

(1) Poor mixing of the internal standard in the sample.

(2) Reaction between the internal standard and the sample components.

(3) Variable purity of the internal standard, etc.

For a more established method, chromatographic problems are more likely to occur, with some common chromatographic problems (e.g., leakage) having a greater effect on the absolute area and less on the area ratio.

However, suppose the change in absolute area is large enough to cause a significant change in the area ratio. In that case, there must be some significant chromatographic problem, such as too large a change in injection volume, a large difference between sample component concentration and standard internal concentration, detector non-linearity, etc. The injection volume should be small enough and remain constant to not saturate the detector and integrating device.

Suppose the method is considered reliable and the chromatogram appears normal. The integration device and settings, slope, and peak width positioning should be checked in that case. The strongest evidence of doubt about the integration device is that the area ratio is variable. In contrast, the peak height ratio remains relatively constant.

5, Advantages

The standard internal method is a method that combines the advantages of the peak area normalization method and the standard external method. It is analyzed according to the peak area normalization method after the addition of the internal standard, which avoids accidental errors due to the consistency of the feed and the effect of the sample matrix. As a result, it also has higher analytical precision and is a more desirable method for quantitative analysis.

Variations in injection volume and small changes in chromatographic operating conditions have little effect on the quantitative results, especially when internal standards are added before sample pre-treatment (e.g., concentration, extraction, derivatization, etc.), which can partially compensate for the loss of the component to be measured during sample pre-treatment. If high-precision results are to be obtained, internal standards of tree species can be added to improve the precision of the quantitative analysis.

Disadvantages: Each determination requires accurately weighing the internal standard and the sample with an analytical balance, which is time-consuming and cumbersome. It is also necessary to have a suitable specimen and internal standard to conduct quantitative analysis using the standard internal method.

External labeling method

1, Definition

In contrast to the standard internal method, the standard external method does not add the standard to the sample under the same chromatographic conditions as the sample under the test. Still, it determines the content of the measured component by comparing the peak area with the peak area of the measured component. The external standard is the same substance as the measured component. Still, it is required to have a certain degree of purity. The concentration of the external standard should be close to the concentration of the measured substance to facilitate the accuracy of quantitative analysis.

2, Types

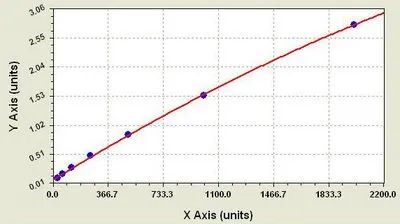

The standard external method is divided into the working curve and the external standard point method. The working curve method uses the control substance to prepare a series of concentrations of the control solution to determine the working curve, find out the slope, and intercept. Under the same conditions, the same volume of sample solution as the control solution is accurately injected. The concentration is found from the standard curve according to the signal of the component to be measured or calculated using the regression equation.

3, Applicable range

The standard external method is suitable for routine analysis, and its use for measuring components can also give satisfactory results. The accuracy of this method depends to a large extent on the control of the operating conditions. The operating conditions for sample analysis must be strictly controlled by those used for plotting the calibration curve. Non-linear calibration curves are given when peak height is sensitive to the operating conditions and when there is a large response to trailing peaks, column overload, and detectors when peak area calculations often give better results. However, it isn’t easy to measure the peak area accurately for overlapping peaks, and the separation must be improved to achieve the desired result.

4, Characteristics

The source of error in the standard external method, apart from variations in separation conditions, is the repeatability of the injection. With syringe injection, the error of the standard external method is within approximately 0.5%. However, a precision of 1% can be obtained using a quantitative injection valve; if the separation parameters are also carefully controlled, analytical precision of ±0.25% can be achieved.

The external standard requires very stringent instrument repeatability. It is suitable for large numbers of samples, as the instrument will change with use and therefore requires periodic calibration of the curve. This method is characterized by simplicity of operation, ease of calculation, no need to measure calibration factors, and is suitable for automated analysis. However, the instrument’s reproducibility and the operating conditions’ stability must be guaranteed. Otherwise, the experimental results will be affected.

How to choose

The advantage of the standard internal method is that the results are more accurate, as they are calculated by measuring the relative values of the internal standard and the peak area of the measured component, thus eliminating, to a certain extent, the errors caused by changes in operating conditions, etc. The disadvantages of the standard internal method are that the procedure is cumbersome, the internal standard and the sample have to be weighed accurately for each analysis, and there are sometimes difficulties in finding a suitable internal standard.

The standard external method uses the standard’s peak area or height and its corresponding concentration to make a standard curve. The sample’s peak area or height is measured, and its corresponding concentration is found on the standard curve, the most commonly used quantitative method. The standard external method is simple, but the sample volume requirements are very accurate and to be strictly controlled under the same operating conditions as the standard. Otherwise, it causes analytical errors and does not get accurate measurement results.

The standard internal method corresponds to the standard external method. The standard external method must be compared with the sample and the standard. Still, sometimes it isn’t easy to ensure that the sample and the standard in the volume are the same. After all, to have the error, use the standard internal method, based on the standard external method, in the sample. The standard in the addition of a substance, through the addition of the substance peak area or peak height changes, we can see the standard and the sample into the volume of the difference, but at the same time, will introduce the addition of the substance in the volume of the sample The change can see the difference between the volume of the standard and the sample in peak area or peak height of the added substance. This is why external standards are generally used for quantification. Still, suppose the injection volume is difficult to control. In that case, internal standards are used to eliminate the error in the injection volume.

Summary

Internal and external standards are both quantification methods, and it is impossible to generalize which method is better or worse.

The application of the standard external method can meet the requirements. After all, the first choice or standard external method is simple and saves trouble. For high precision requirements, where the accuracy of the results can have a significant impact, and where laboratory conditions are not ideal, internal standards are still necessary. Regardless of the method used, validation and confirmation of the method are important. As long as the method is validated and confirmed according to procedures, there is scope for its application.

Post time: Jan-28-2023