Liquid chromatograph is a commonly used laboratory instrument, but even experienced “veteran drivers” can easily overlook some small details. Don’t underestimate these overlooked details, which may affect your chromatographic equipment or analysis results. ! Some glitches are also caused by not paying attention to details. Newbies in chromatography also need to pay attention!

The mobile phase must be filtered! Some chromatographers may think, am I not using an analytical-grade pure water mobile phase? Why filter? The answer is: the newly prepared mobile phase is easy to breed bacteria after being allowed to stand indoors for a few days. Especially in the south, the summer heat is more likely to breed bacteria and contaminate the mobile phase! UHPLCS recommends: The mobile phase is ready to use. If you want to use the mobile phase with a longer interval, it must be filtered! Otherwise, the growth of bacteria will block the pores in the chromatographic column packing and eventually damage the chromatographic column.

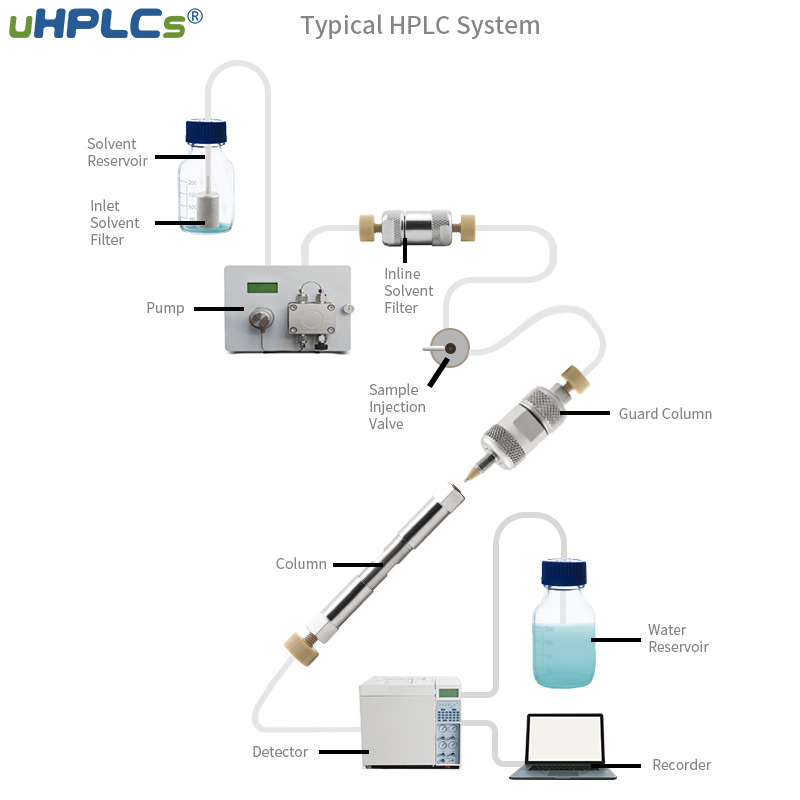

What is the filter for the mobile phase? Inlet Solvent Filters (also called chromatographic sinker) can be used for filtration. UHPLCS solvent filter is mainly used for high performance liquid chromatography or liquid chromatography mobile phase filtration, which can prevent small solid particles, bacteria, impurities, etc. in the solution Contaminants enter the HPLC system, and the filter head is made of high-quality 316L stainless steel, which is suitable for most solvents. In addition, the mobile phase suction filter head should also be cleaned regularly to prevent bacteria from clogging on the suction filter head, which will not only cause re-pollution but also reduce the service life of the product.

Avoid running out of mobile phase! When the pump is working, pay special attention to avoiding the mobile phase in the solvent bottle from being used up, otherwise the empty pump will wear the plunger, cylinder or sealing ring, and eventually cause leakage and pump damage. If the mobile phase is found to be empty, stop the pump immediately, drain the air from the pump first, use pure methanol as the mobile phase, and flush the entire flow path at a low flow rate. The damage to the pump is irreversible! Remember to operate carefully at ordinary times, you can set the analysis time of the chromatograph, and shut down regularly. When the instrument is running, pay attention to observe whether the pressure fluctuation changes are normal. If there is fluctuation and liquid leakage occurs, most of the sealing ring is damaged, and it should be replaced in time!

Speaking of the problem that the pump will be damaged if the mobile phase is empty, it has to be mentioned that the pump should be cleaned regularly. If the mobile phase containing the buffer stays in the pump for a long time, it may evaporate or leak and precipitate salt crystals, which can damage the seal ring and plunger. After the analysis, it is necessary to clean the pump with pure water, and add maintenance solvent to the pump.

The factors that damage the pump are not only salt crystals, but also some particulate impurities that have not been filtered in the mobile phase. An online filter can be installed between the pump and the injection valve to effectively prevent particles from entering the system. UHPLCS UHPLC ultra-high pressure Chromatography Inline Filters can remove particles in the solvent, prevent them from entering the injector, thereby preventing clogging. The product is resistant to high pressure, does not leak, has small dead volume, low back pressure, is not easy to block, and has good corrosion resistance. The 2.1 ultra-high pressure in-line filter can even withstand pressure of 15,000 psi.

That’s it for today’s sharing! It is important to want to perform chromatographic analysis experiments conveniently and quickly, but some details cannot be ignored or lazy. This is also to protect the service life of liquid chromatography instruments. After all, the instrument is very expensive, and use it and cherish it!

Post time: Sep-22-2021