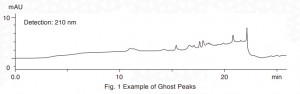

What do you mean by ghost peaks? When doing the gradient elution of liquid chromatography reversed-phase system, sometimes we will encounter the situation that the instrument does not feed the sample but also has the peak, affecting the quantitative results. It can also make the analysis impossible because of its ghostly quality, called a ghost peak. Then we will understand the possible reasons for the appearance of ghost peaks and methods of elimination.

In the suspicion that the peak shape is abnormal is not a ghost peak, we can first carefully verify whether the operating conditions are consistent with the analytical method, whether the instrument is in normal working condition to see whether there is an operational error, to determine whether it is not the errors mentioned above, the instrument does not feed the sample, or into the mobile phase, or only run the method to see whether there is still an inexplicable peak in the baseline to determine whether it is a ghost peak. From the perspective of the frequency of ghost peaks, it can be considered from two major aspects: the mobile phase and liquid phase system.

The reasons for ghost peaks are various. According to my experience and literature reports, the reasons are summarized as follows: 1, the mobile phase, sample diluent, instrument or container impurities, when the gradient begins due to the organic phase ratio is not high, the elution capacity is not strong, impurities in the column head enrichment, with the mobile phase ratio changes, the elution capacity is enhanced, the enriched impurities are eluted, thus forming ghost peak.

2, the mobile phase degassing is not complete. The solubility of air in the organic phase and water is different. When the water and organic phase are mixed, bubbles are generated.

3、Operation problem.

Reagent issues

1, Organic solvent

The methanol preparation process is relatively simple compared to acetonitrile, and the impurity content is also less. However, because the UV absorption range of methanol is wider than that of acetonitrile, so when using a UV detector, especially when the wavelength is lower, try to use acetonitrile as the organic phase, and the drift is too large with methanol. The quality of acetonitrile used in gradient chromatography requires high quality. Generally, special acetonitrile with imported gradient chromatography can reduce the appearance of ghost peaks.

2, Water

Many units use homemade distilled water as the aqueous phase, but the results are not very good. The reason is that some low boiling point organic impurities can not be removed by distillation. As far as possible with HPLC-grade pure water, no conditions can also use in Wahaha or Watson’s water. However, if the chromatographic conditions are more stringent is also likely to be a problem.

3, Other reagents

Buffer salts, TFA, EDTA, and other reagents will also greatly impact the mobile phase. Try to use high-purity reagents to prepare the mobile phase.

4, mobile phase configuration after pre-sonication degassing

5, holding the mobile phase containers or measuring instruments is contaminated

This contamination may come from detergents, chromic acid wash, or other residual impurities after laboratory personnel use. Mobile phase container cleaning generally with clean water + organic solvents on the shabbing. Too many cleaning steps may cause secondary contamination. Sometimes the plastic cover fragments of the mobile phase container may be the source of impurities.

6, pH meter

Many pH meters use polycarbonate as a shell. However, polycarbonate is soluble in organic solvents, so try to use a glass pH meter to measure the pH of the mobile phase.

7, Filter membrane

Poor quality or the wrong type of filter membrane is often the reason for ghost peaks.

8, placed for too long

The mobile phase is exposed to air for too long, it may absorb organic impurities in the air, and sometimes the additives in the mobile phase, such as TFA, will oxidize over time and thus produce impurities.

Instrument problems

1, the mobile phase of the hplc tubing is contaminated.

Prolonged use of mobile phase with high water content (especially the addition of buffer salt), bacteria are easy to breed in the pipeline, bacterial metabolites or cell debris can cause ghost peaks.

2, transfer pump failure, resulting in system pressure instability, thus creating ghost peaks.

3, check valve blockage.

Causes system pressure instability, resulting in ghost peaks. The early Shimadzu liquid phase check valve seems unable to use pure acetonitrile as the mobile phase and now should have been improved.

4、The inline degasser is not completely degassed.

5, the ratio of the two mobile phases of the organic phase is too different.

For example, A is 100% water, and B is 100% acetonitrile. The gradient conditions allow for the minimization of the gap between the two mobile phases reducing the difference in the solubility of air in the two mobile phases, thereby reducing the generation of bubbles.

6、Contamination of solvent bottles and solvent inlet filter.

With the use of pure water phase or mobile phase with high water content for a long time (especially the addition of buffer salts), bacteria are easy to breed, and bacterial metabolites or cell debris stay, resulting in contamination. If the mobile phase is not replaced with a new one after a long time or if the mobile phase bottle is not cleaned but added directly to the replenishment method, it may also lead to ghost peaks.

In this case, developing a good mobile phase bottle cleaning and replacement plan to replace or clean is recommended.

In addition, solvent filter heads can also have contamination. Remove the solvent filter in the solvent bottle to see if the ghost peak can become smaller or disappear. If it becomes smaller or disappears, you can replace the hplc solvent inlet filter in the solvent bottle.

7, from the sample residue.

The sample can be residual in each plate of the instrument. We can check them one by one.

a. Confirm that the problem comes from the sample residue of the inlet.

Connect the inlet and outlet lines of the injector directly with two-way. If the ghost peak problem is solved, suspect the inlet needle, needle seat, and six-way valve rotor contamination problem and perform the relevant cleaning and replacement.

Tips: Before suspecting the residual problems of the injector, check whether the connection line is normal. Otherwise, it will also lead to ghost peaks.

b. Confirm that the problem comes from the sample residue of the hplc column.

The chromatographic column can be an enrichment for strongly retained contaminant components within the mobile phase or system flow path, flushed out as the organic phase ratio changes with the gradient program.

Replacing the column with a two-pass is a contaminated column if the ghost peak is eliminated. This can be solved by cleaning the column or replacing it with a new one.

On a side note, that is, uHPLCs has launched a product for ghost peaks, that is, the ghost peak trap column, in addition to the above steps, plus the ghost peak trap column is the icing on the cake!

Post time: Nov-12-2022