The production technology of gas chromatography columns has long entered a stable period, while liquid chromatography columns are still in the competition stage, with fierce competition and numerous technical innovations.

Each company has its unique technique, and some new terms will pop up from time to time. In this issue, let’s talk about those new technologies of liquid chromatography columns over the years.

The earliest liquid chromatography columns, like the gas phase, had columns made of glass and were not resistant to high pressure. As liquid chromatography runs at higher and higher pressures, almost all liquid phase columns are now made using metal. And they are becoming shorter and shorter, and the particles filled inside are getting smaller and smaller.

Amorphous silica gel

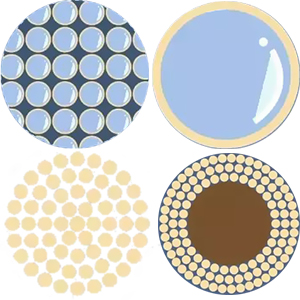

Early fillers used amorphous silica gel

Thin Shell Filler

The thin-shell packing was later invented by applying a layer of silica gel on the surface of glass beads.

This design dramatically reduces the vortex diffusion term, i.e., the A term of the van der Merwe equation, and increases the column efficiency by orders of magnitude. However, the silica gel in this packing is only a thin layer, which means that the stationary phase capacity is minimal, and only very low concentrations of samples can be separated.

All-porous spherical silica gel

This led to the development of fully porous spherical silica. For example, a classic 5um fully porous silica column is often available in the laboratory.

According to van’s equation, it was found that smaller particle sizes could lead to higher column efficiencies.

However, as the particle size gets smaller, the resistance increases, requiring higher-pressure liquid phase systems. Although it is said that the column efficiency of small particle-size columns is high, it is costly to change a whole system to use one column. So, is there any way to reduce the column pressure so that ordinary HPLC can also use efficient small particle-size columns?

Core-shell columns

Inspired by the once thin shell packing, some manufacturers came up with a brand new design idea, a solid granular column or nuclear shell column.

Since then, it has set off a wave of research and development in the industry, and now many manufacturers have launched similar columns, a technology named differently by each family. Still, it means the same thing. There is a hardcore, while the surface is porous.

The core-shell packing is more uniform in size and has a lower vortex diffusion than the fully porous particles. The presence of a solid core makes the packing pore volume smaller, reducing the longitudinal molecular diffusion in term B of the paradigm equation and the mass transfer resistance in term C. It can provide both higher column efficiency and greatly reduce the column pressure, making it possible to achieve rapid analysis effects similar to those of high-pressure liquid chromatography on conventional liquid chromatography, so these core-shell columns, also often called rapid analysis columns.

If they use conventional HPLC, student laboratories can boldly try this kind of solid particle column, which can greatly improve the analysis speed and have good column efficiency.

However, the use of this type of column, from hardware to parameters, and the traditional column are different, and we will have the opportunity to tell you later.

The innovation of technology comes from the need for application. Although silicone columns are still the mainstream, there are obvious disadvantages.

The biggest problem with silica gel is that it is resistant to acids but not bases. The usual tolerance range is pH 2-8. The silica gel skeleton will start to dissolve at too high a pH. How can we make the column more resistant to alkaline mobile phases? This is of great importance for the analysis of alkaline drugs.

One idea is to look for alternative materials to silica gel, such as polymers.

In addition to being more chemically stable, polymeric stationary phases have special advantages in analyzing large molecule compounds. Many macromolecules are sterically structured or have a specific shape. If complementary shapes are bonded to the surface of the polymer, it is possible to retain the molecules of a specific shape.

Another idea is to improve the technology of silica gel synthesis.

The reason why conventional silica gel columns are not resistant to alkali is that the pH is so high that the Si-O bond of the silica gel backbone breaks. In the silica gel spheres hybridized with organic particles, the more stable Si-C bond replaces part of the Si-O bond, and the pH range of the column can be broadened to 1-12. there is no 100% perfect choice, and each design has its strengths and weaknesses. Students who still want to know details are welcome to leave us a message~.

Post time: Nov-03-2022