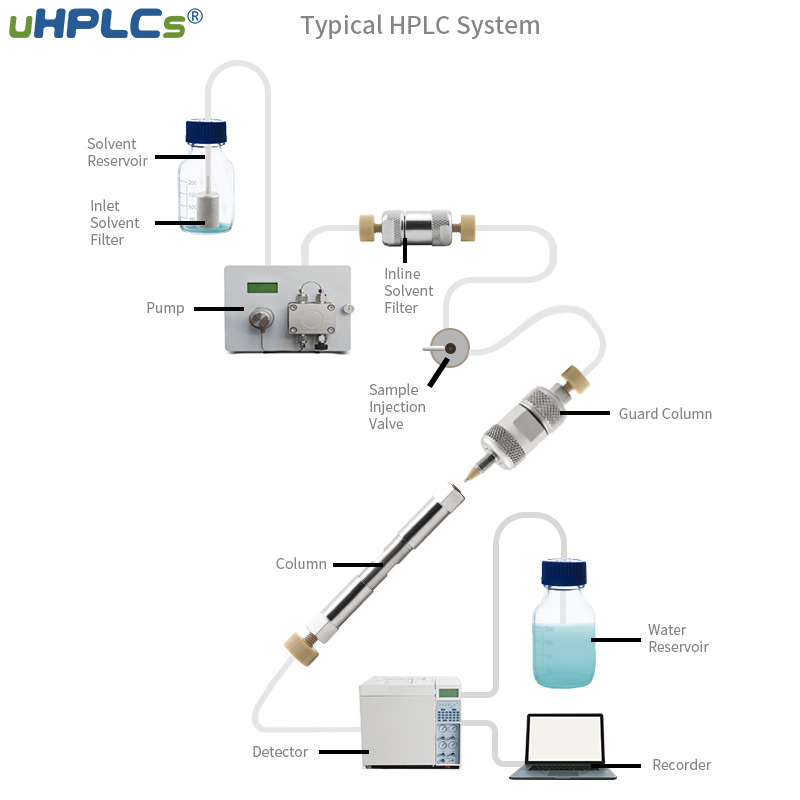

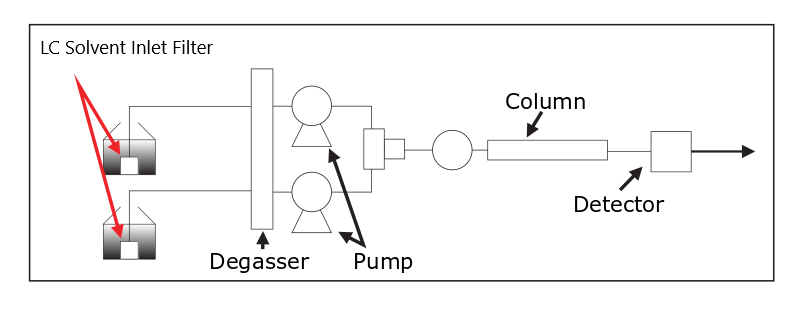

The liquid chromatography system is a closed system. From the very beginning solvent bottle to the last waste bottle, it is kept completely closed during the period. The mobile phase should flow in the system without leakage or external gas entering the system. An air leak has occurred. However, this is an ideal liquid phase system. In actual operation, some minor problems and glitches will still occur, resulting in liquid leakage or gas leakage.

The main reasons for leakage are as follows:

(1)The joint leaks fluid

Generally, liquid leaks at the chromatographic column joints, which may be caused by damaged, loose joints, or mismatched interfaces. Just check what the problem is with the connector at this time, and it’s almost done. If the interface is damaged, you can replace it with a new one. If it is loose, tighten it. If it is a mismatch problem, it is best to use a matching connector for the chromatographic column or use a peek connector, which has high adaptability. UHPLCS PEEK threaded chromatographic column plug connector is universal and reusable, compatible with almost all brand chromatographic columns, low dead volume connection, and chemical resistance can not react with solvents. Hengpusheng chromatographic column connector series include: PEEK 1/16″, 1/8″, 1/4″ threaded connector, zero dead volume PEEK internal/external thread connection union; stainless steel 1/16″, 1/8″ , 1/4″ threaded connection head, stainless steel non-dead volume internal/external thread connection union; PEEK / stainless steel pressure rin (2) Pump leakage

(2) Pump leakage

Pump head leakage is generally caused by poor sealing. First, check whether the one-way valve and joint are loose, but they should not be tightened too tightly during adjustment to avoid mutual wear and damage.

(3) Leakage of the injection valve

The rotor sealing ring is worn too badly or has been damaged, resulting in a weak seal. In this case, the injection valve can only be reinstalled or replaced. There are also cases where the waste liquid is siphoned or blocked, causing the waste liquid to flow backwards. At this time, it is necessary to keep the waste liquid pipe higher than the waste liquid level, or replace or unblock the waste liquid pipe to ensure the normal discharge of the waste liquid.

After talking about the leakage, we will now come to the leaking part. Leakage is when external gas enters the flow path of the instrument to form bubbles. Why is it leaking? The main reasons are as follows:

(4) Suction filter

When the solvent suction filter is pumping solvent, irregular but continuous small bubbles are generated in the flow pipe. If the degassing step has been carried out, pay attention to whether the suction filter is contaminated or damaged. Solvent filters are commonly used devices in laboratories and are mainly used for mobile phase filtration. UHPLCS solvent inlet filter can prevent small particles in the mobile phase from entering the HPLC system. The stainless steel solvent filter of UHPLCS will not introduce air into the system, and no bubbles will enter the mobile phase pipeline. The solvent extraction utilization rate of the storage bottle can reach more than 99%, which greatly reduces the waste of solvent at the bottom of the bottle due to the inability to clean vacuum sucti

Equipped with multi-stage pipeline joints, compatible with a variety of internal diameter solvent mobile phase pipelines, and can match different specifications of pipelines without replacing the suction filter.

(5) Transparent flow pipe

Refers to the section of pipeline between the filter head and the delivery pump. Some staff made mistakes in the operation and caused the entire pipeline to be full of air. The delivery pump was clearly working but the liquid in the mobile phase bottle was not at all. This is mainly because if the instrument is not used for a long time, the liquid in the pipeline will be completely dried out. It is impossible to distinguish between the air-filled pipeline and the liquid-filled pipeline without careful inspection. This situation is very dangerous for the delivery pump and can cause irreversible damage to the pump.

Liquid chromatograph is widely used in various biological, pharmaceutical analysis and chemical fields. For some of its faults and problems, operators must learn from it all the time. Only by understanding it can the instrument be used to the fullest extent and save costs in the long run. , Avoiding malfunctions in advance can effectively maintain the chromatographic instrument and use it for a longer time.

Post time: Oct-07-2021