When people are doing the liquid phase, I wonder if someone is wondering the same question as I.

Why are the internal diameters of the columns all some very fragmented numbers?

For example, 4.6mm, and 2.1mm.

I have never seen 5mm, 10mm, and other integers that look pleasing to the eye.

I believe most people have this question.

So, is it possible that the people who designed the columns are so brain-dead that they have to pick some odd numbers to amuse everyone? Most of the columns on the market have these strange inner diameter specifications, but the columns with integer values seem alien to everyone.

Why is that? There must be some reason. So what is the reason?

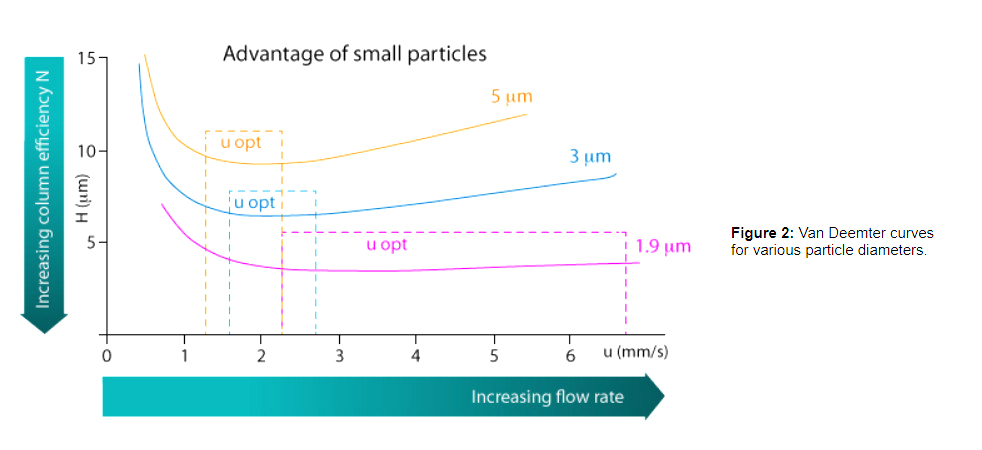

In the basic theory of liquid chromatography, we hear a thundering name called Jan van Deemter; for simplicity, we call him Lao Fan, who once drew a pair of hooks on paper to explain the relationship between column efficiency and flow rate of chromatographic columns. It has become one of the most classic theories in liquid chromatography separation.

The Van Deemter equation is based on a 5um packed column. Why choose 5um packing? The main reason is that this packing was created in the 1980s and flourished in the 1990s, and it is still a classic.

So let’s explain this classic pair of hooks, which is drawn on an axis with the horizontal coordinate indicating the linear velocity of the spectral band shift and the vertical coordinate indicating the theoretical tower plate height. Nani? Line velocity, theoretical tower height, what are these?

These two terms are new. So, we have to translate them into a grounded vocabulary, and then they can be approximately understood as: flow rate and column efficiency. For a given column (length, packing particle size fixed), the greater the flow rate can produce higher analytical velocity, the smaller the plate height can produce greater column efficiency; so, in the old Fan’s hook, the greater the value of the horizontal coordinate, the faster the analytical velocity; the smaller the value of the vertical coordinate, the column separation effect is better.

Knowing this, we can roughly understand the meaning of the hook drawn by Fan: corresponding to a fixed column: the column efficiency increases with the increase of the flow rate, and after reaching a maximum value, it starts to decrease with the increase of the flow rate, and the flow rate value that allows the column to reach the maximum column efficiency is called the optimal flow rate. It is called the optimal flow rate range. Therefore, the deeper meaning of Lao Fan’s pair of hooks is: I will draw a big pair of hooks for whoever uses the column at the optimal flow rate.

Flow rate and internal diameter

Speaking of which, we have been talking about the old van and the flow rate, not yet, and the relationship with the inner diameter. Next, we need to talk about the old van and the flow rate, but before that, we need to understand the inner diameter first.

The horizontal coordinate is called the linear velocity in the big pair of hooks, and we approximate it as the flow rate. In fact, in the process of “approximation,” we omit the factor of the inner diameter or the influence of the thickness of the column.

The linear velocity refers to the speed of the chromatographic peak band movement, usually in cm/min.

And flow rate refers to the volumetric flow rate of the chromatograph infusion, usually in mL/min.

The thicker the column, the larger the car, and the more oil it burns to drive to the same speed, so a thicker column requires a larger volumetric flow rate to produce the same line speed/analysis speed.

Back to the head to see the big pair of hooks drawn by the editor and find a ruler to compare, I found that for the 5um packing column, the best flow rate corresponds to about 6cm/min. However, this is the line speed, and we use the chromatograph required to set the volume flow rate. Just now, we said that the volume flow rate and column inner diameter are related, then the question arises: column inner diameter which is good?

The people who designed the column did not just design a 1, 2, 5, or 10mm such as they looked cool to everyone and were happy to see the internal diameter of the number. In this issue, they adhered to the “industry conscience.”

When you enter the flow rate on the chromatograph, does it feel good to enter 1mL/min or 1.18mL/min? I believe that if the students are not self-mutilating, they will feel more comfortable with 1mL/min.

1mL/min corresponds to the optimal flow rate of a 4.6mm ID column, while 1.18mL/min corresponds to the optimal flow rate of a 5mm ID column (both are said to be 5um packed columns).

Now you understand why I said the column designers have an “industry conscience” to let everyone use cool. They would rather let themselves in the column when “not cool,” this is what kind of internationalism spirit ah ~.

Later, with the progress of the instrument, the instrument can control the flow rate with higher and higher precision, so, for the mobile phase savings and mass spectrometry compatibility and other needs, also began to appear smaller inner diameter of the column, in the design of these columns, still adhering to the consistent industry conscience, as far as possible to let people enter some more “whole” when the instrument control. “The inner diameter of the column is still not very regular. 3.0 mm corresponds to 0.4mL/min, 2.1mm corresponds to 0.2mL/min, and 1.0mm corresponds to 0.05mL/min (this seems to be quite neat on both sides, it is simply a gospel for OCD patients ~ However, in fact, this specification of the column is far from the other specifications (The full range of packing…)

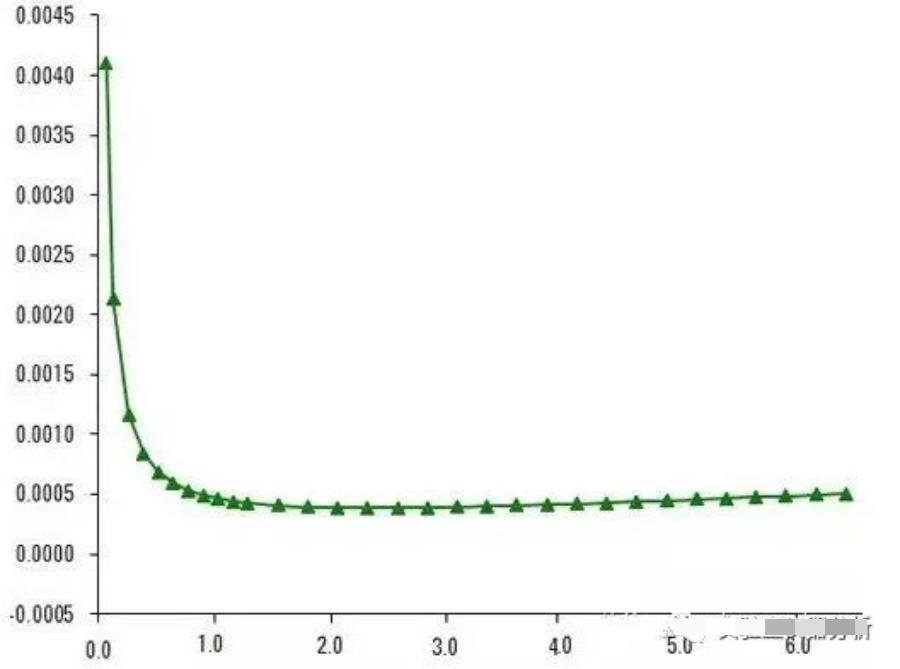

Later, UHPLC appeared, the pair of hooks obviously out of shape.

We can see that the optimal flow rate of UHPLC differs from that of 5um HPLC packing. According to the theory of industry conscience, the inner diameter of the UHPLC column should also be changed to continue to make everyone feel good. However, the inner diameter specifications of the UHPLC column we see are still the same: 4.6, 3.0, and 2.1.

Is the industry conscience gone?

Don’t panic. Go back and use the ruler to compare the hairy version of the hook. We will see that for UHPLC, the optimal flow rate is about 12cm/min in this place, and, due to the expansion of the optimal flow rate range of UHPLC, the optimal flow rate value of classical HPLC is still within the optimal flow rate range, so even if we do not change the inner diameter and flow rate, the column efficiency of UHPLC is also very good. If we want to pursue the optimal flow rate, multiply all the actual flow rates by 2. 1 becomes 2 and should not cause any discomfort.

Large I.D. HPLC Columns

We have already understood why the column I.D. numbers are not integers. As we mentioned earlier, small I.D. columns emerge due to solvent savings and mass spectrometry compatibility. The following is to explain it roughly.

1, The large inner diameter column can carry a larger sample volume

Using this feature, we can carry out chromatographic preparation and purification. With a large inner diameter column, a sample can be purified, or use the car as an example, a large bus than a small bread can be loaded with more people.

2, Large internal diameter column has better resistance to “solvent effect” ability

Usually, even if the solvent compatibility is not so good, a large I.D. column is more likely to get a better peak shape.

3、Large I.D. columns are more tolerant to the system diffusion of the instrument.

Due to the use of higher flow rate analysis, the large I.D. column will be smaller due to the dead instrument volume caused by the loss of column efficiency. In contrast, the small I.D. column is particularly sensitive to dead volume, which is why the narrow diameter column (I.D. less than or equal to 2.1mm) is now recommended for high-performance UHPLC instruments.

4, The large internal diameter of the instrument is relatively less sensitive to the impact of delayed volume

Mainly due to the high flow rate, we can try to offset the impact of delayed volume.

5, A large internal diameter can obtain a higher flow rate

For some models of instruments and some special methods, it is easy to obtain better mixing accuracy at high flow rates, mainly due to the hardware performance limitations of the instrument.

Therefore, the choice and use of the inner diameter of the column are entirely based on their actual needs to choose. In some aspects of good performance, there is bound to be a sacrifice in some aspects. According to their instrumentation, the foot is short, an inch long, and the actual needs of choice of the appropriate inner diameter of the column are the right way.

Finally, this is quite a complex problem as to why the uHPLCs will lead to a small hook variation. Just rely on the old Fan drawing the hook has been unable to explain and take out the formula he compiled as an afterthought.

Post time: Oct-06-2022